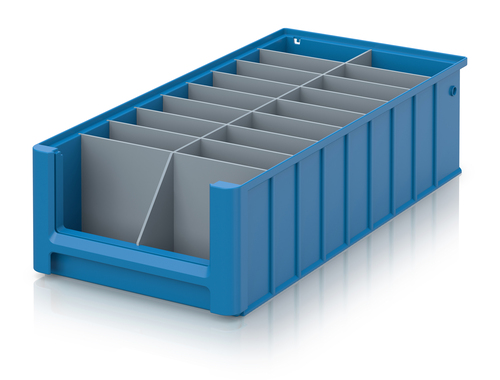

The heart of the system boxes made by AUER Packaging is their innovative coupling system. The system enables the boxes to be quickly and securely attached to one another, on special transport rollers, on hand trolleys with the appropriate attachment – and now on the wall or floor, wherever you wish. The newest member of our range of accessories is an attachment that can be mounted horizontally or vertically. It is equipped with a coupling system that creates a completely secure bond with all products in the system box line that have the same basic dimensions.

July 2022